Julia Rönnberg, Design Engineer

"Now that the K100 has seen the light of day we can also see we succeeded."

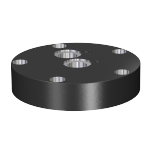

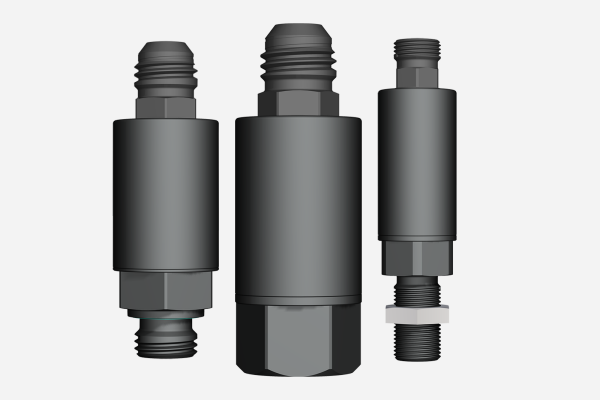

”Work on developing an entirely new swivel began several years ago. In the requirements specification that formed the basis for the development project, high quality, long service life and high performance all at a competitive price were important basic considerations.

Those of us who worked on the development of the K100 are actually more than a little proud of a couple of unique solutions that made meeting and even exceeding all the different requirements possible.

One is our truly unique seal solution that makes it possible to use the swivel at constant high pressure and expose it to bending loads without affecting the impressive service life. Another is the sliding bearing that increases safety by eliminating critical oil leaks, which means low torque even at high pressures. I would also like to highlight the new surface coating that guarantees the swivel’s service life thanks to its good corrosion and wear resistance.

So how do we know the K100 is this good? Well, following extensive testing in both lab environments and out in the field, we’re fully confident that every part of the swivel is able to cope with the pressure required and the torques, loads and other external and internal forces it is exposed to. Try one and see!”

Deutsch

Deutsch Suomeksi

Suomeksi Svenska

Svenska